Going Paperless: The Benefits of e-Forms in Construction

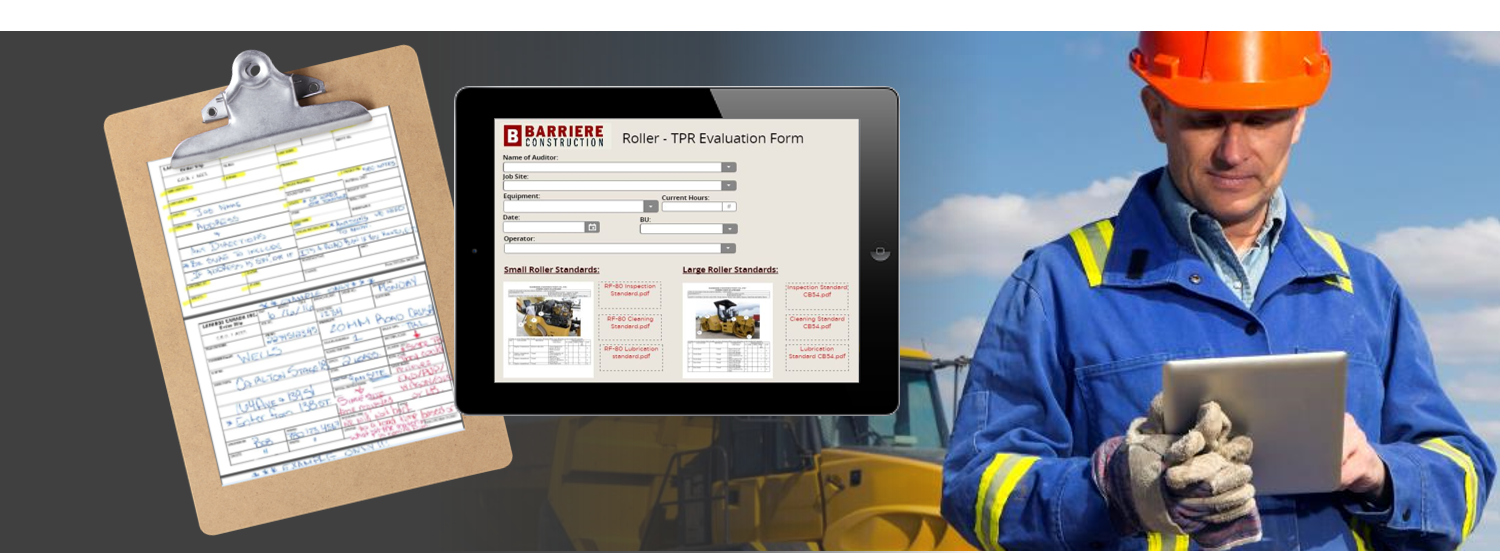

Going “paperless” in the construction industry is an increasingly popular goal, as contractors look to escape the inefficiencies, lag time and errors that paper forms bring, while better leveraging the data those forms contain. At Barriere Construction in Louisiana, safety meetings and equipment inspections are two processes where dramatic improvements have been achieved via the B2W Inform solution for data capture and analysis.

“We added the Inform piece to complement the B2W platform because we had a vast amount of paper forms out in the field that were not getting turned in in a timely manner,” says Heath Wahden, CFO at Barriere. “The lag time and the paper format limited us from accessing and leveraging the vital information on the forms to manage our business more effectively.”

Barriere Construction Videos

Making the Switch to Digital Forms for Safety Meetings

Regularly scheduled safety meetings or “toolbox talks” are a staple on construction sites and a proven tool for preventing injuries, complying with regulatory requirements and sustaining a culture of safety. Managing the process, getting proper materials to the job sites and documenting the meetings; however, can be an ongoing administrative headache.

At Barriere, paper forms for Monday morning toolbox talks were mailed to foremen. After the meeting, they had to get the form from the foreman to a superintendent, a truck and the office to be re-keyed into a system. The lag time often exceeded two weeks. Now, foremen pull up the toolbox talks on an iPad, present the topic and have crew members sign off electronically. The forms are submitted instantly to the office by 7:00 a.m., enabling timely analysis and the opportunity to identify trends and head off potential threats to safety before they occur.

Eletronic Equipment Inspection Forms

Benefits of moving from paper forms to electronic forms for equipment inspections have been similar at Barriere. Rather than relying on generic, one-size-fits-all forms, the company creates customized forms to extract the exact information they need about each specific piece of equipment. Foreman and operators access the right form at the right time online, instead of having to update and carry a large library of paper forms. Filling out electronic forms is faster and easier too. Drop-down menus, check boxes, mandatory fields and other functionality keep the data structured and consistent while preventing errors or omissions. Rich data like photos and videos can also be included.

Most importantly, the switch to digital forms has closed the gap between the field and the office and between identifying a problem and correcting it. “Getting inspection and audit forms instantaneously in a digital format with Inform has really been a game changer,” says Brett Todd, Resource Operations Center manager. “We can create work orders right away and have been able to cut the days-to-complete timeframe from two or three weeks to less than a week, on average.”

Leave a Reply

Want to join the discussion?Feel free to contribute!